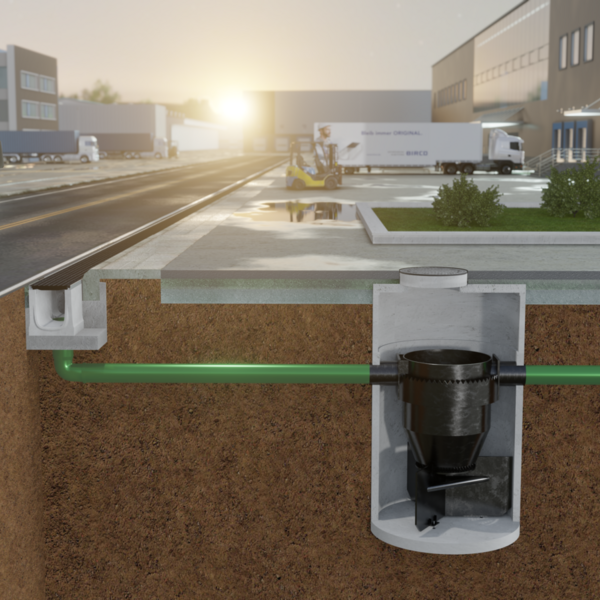

BIRCOhydroshark |Sedimentation plant set in concrete chambers DN 800 - 3.000

The system for semi-centralised rainwater treatment

Facts

- Compact sedimentation system set in a concrete chamber

- Available in 6 sizes

- Hydrodynamic separator

- Removal of solids (AFS) through physical treatment

- No height difference between inlet and outlet

- Installation under traffic areas

- Easy inspection and maintenance

- Connectable area of up to 22,500 m², depending on the individual system and degree of contamination

Certified system for rapid planning progress

- Classification in DWA-M 153 or DWA-A 102 possible

- Determination of the flow rates according to ATV-DVWK-M 153

- Prevention of remobilisation tested in accordance with the DIBt test procedure

- Function of the flow separator

- Oil retention function determined in accordance with DIN 858-1

- IKT tested in accordance with NRW separator decree (LANUV list)

- Maximum hydraulics tested for Qmax inlet pipe

BIRCOhydroshark | Details

Precast concrete parts manufactured in accordance with DIN V 4034 Part 1

Maintenance intervals 1 - 5 years depending on the connected area and local degree of pollution.

Operating principle

The BIRCOhydroshark is a stormwater treatment system based on the hydrodynamic separator principle

- The incoming stormwater is deflected into a radial flow pattern, a swirl separation technology.

- Solids settle down into the sludge chamber, floatables are retained at the surface.

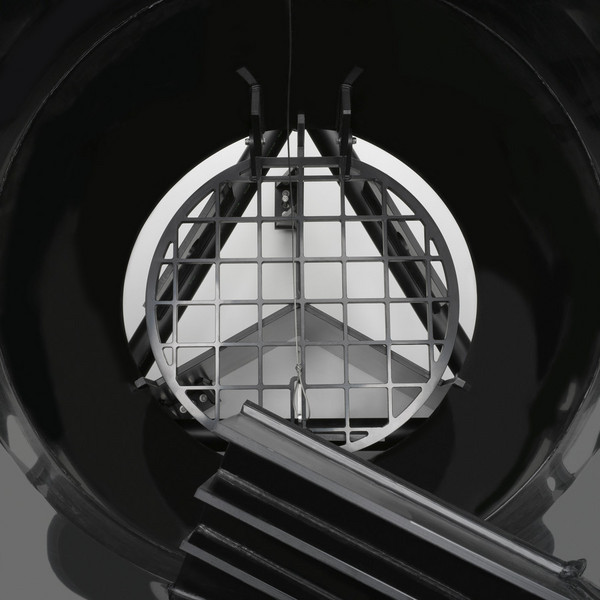

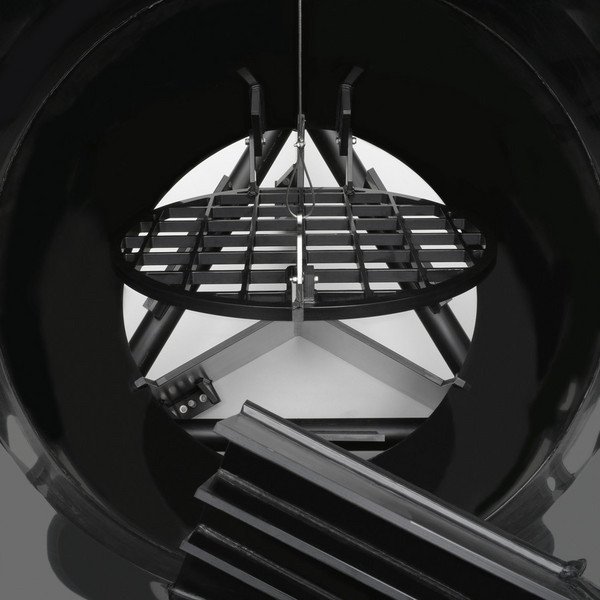

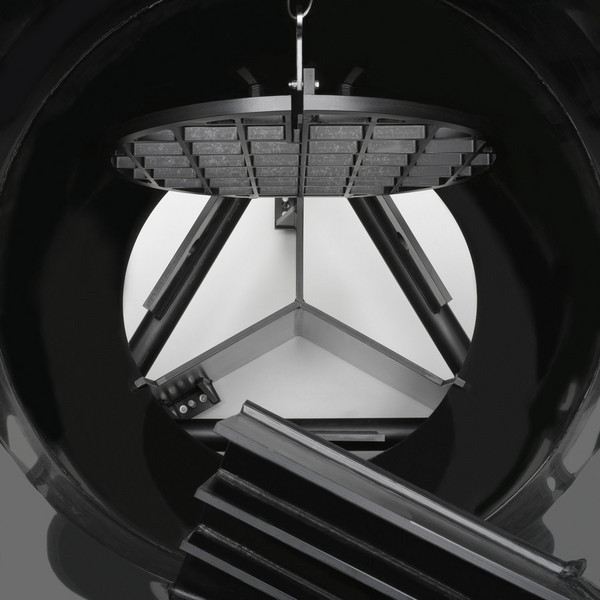

- Solids are collected in the sludge trap, which is hydraulically separated from the treatment chamber by flow breakers and a grate, so that remobilization does not occur.

- The water rises evenly on the side walls.

- The purified water is collected in an annular space by a weir and then transported to the outlet.

- Discharge of the treated water into the stormwater drain, infiltration trench or infiltration system.

Hydrodynamic Particle Separator

Process of opening the grate to access the sludge chamber (cleaning/suction and maintenance)

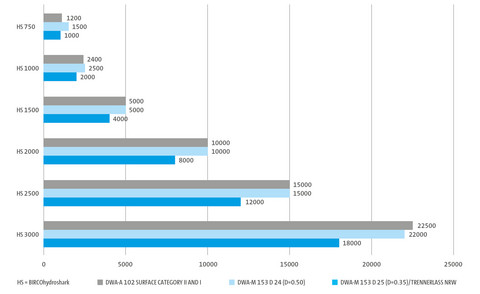

Selecting your BIRCOhydroshark system

Realisable connection surfaces of the individual systems according to DWA certification

Heavy rainfall over urban centres is on the rise. Careful planning is required to ensure that traffic and, in particular, logistics areas do not come to a standstill. The technical department at BIRCO supports you in choosing the right products. Various parameters are taken into consideration:

+ Which systems are used to collect the water?

+ According to which input is the filter system calculated? (DWA-A 102, DWA-M 153 or DWA-A 138)

+ What is done with the treated rainwater?

+ Is the sewer system designed accordingly or does it require retention to prevent damage from flooding?

Type

| min. installation depth*

| Outer diameter*

| Weight*

| max. recommended Q flow rate | max. possible Qmax flow rate

| Article number

|

|---|---|---|---|---|---|---|

BIRCOhydroshark 750 (DN 160) | 2540 mm | 1100 mm | 3100 kg | 25 l/s | 30 l/s | 606500 |

BIRCOhydroshark 750 (DN 200) | 2540 mm | 1100 mm | 3100 kg | 25l/s | 30 l/s | 606505 |

BIRCOhydroshark 1000 (DN 200) | 2570 mm | 1300 mm | 4330 kg | 40,0 l/s | 60 l/s | 606510 |

BIRCOhydroshark 1000 (DN 250) | 2570 mm | 1300 mm | 4330 kg | 51,3 l/s | 60 l/s | 606515 |

BIRCOhydroshark 1500 (DN 315) | 2560 mm | 1800 mm | 7200 kg | 98,0 l/s | 125 l/s | 606520 |

BIRCOhydroshark 2000 (DN 315) | 2670 mm | 2300 mm | 9090 kg | 147 l/s | 250 l/s | 606530 |

BIRCOhydroshark 2000 (DN 400) | 2670 mm | 2300 mm | 9090 kg | 220 l/s | 250 l/s | 606535 |

BIRCOhydroshark 2500 (DN 400) | 2760 mm | 2800 mm | 12340 kg | 220 l/s | 375 l/s | 606540 |

BIRCOhydroshark 2500 (DN 500) | 2670 mm | 2800 mm | 12340 kg | 378 l/s | 375 l/s | 606545 |

BIRCOhydroshark 3000 (DN 500) | 2820 mm | 3300 mm | 16720 kg | 378 l/s | 560 l/s | 606550 |

BIRCOhydroshark 3000 (DN 600) | 2820 mm | 3300 mm | 16720 kg | 674 l/s | 560 l/s | 606555 |

* incl. concrete chamber